YOUR TURBO DOESN'T FLOW ENOUGH AIR? It runs out of steam up top? We're going to fix that by making some. Hot air takes up more space than cold air. Inject water/methanol and the back pressure will instantly drop. The wastegate then forces the turbo to spin faster to raise it back to original setting. Any air restriction that the device imposes is more than offset by obvious flow gains.

The net result is greater mass air flow at the same final boost level. Spool characteristics are left identical to stock, but peak flow is "BIG UPPED". It's important to spray only as maximum boost is approached. So, this kit is best paired with a Solenoid Upgrade. If not a solenoid, then at least a Check Valve will be needed to keep the system from draining under vacuum or when parked on a slope, etc.

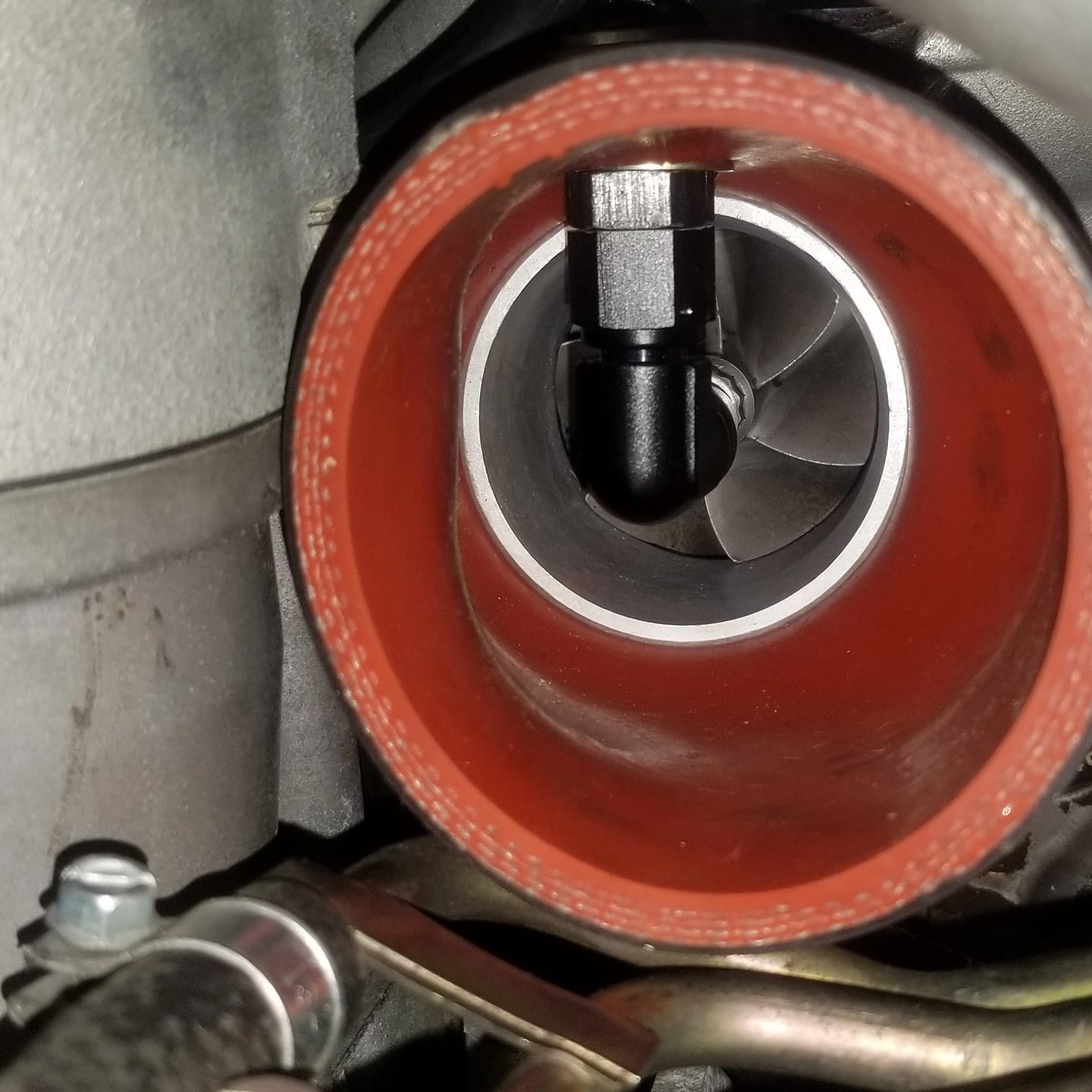

Spray is aimed directly at the center nut, the slowest moving and strongest section of the rotating assembly. Over tens of thousands of miles, the leading edges will likely attain a light polish.

Tip erosion is completely eliminated by positioning the spray point directly in front of the spinning wheel. (Whereas, a stand off installation leads to wall wetting, trickling, and constant impact on the blade tips. -the weakest and fastest-moving portion of the system.)

Note: A 1/4" straight fitting is supplied standard. If a 3/16" compression fitting or 4AN fitting is preferred, just ask and we'll substitute. All other threads are 4AN.

Note2: A spray nozzle is NOT supplied. -because we don't know which you'll need until you ask us for help about it. Do that. Contact us.

Note3: With a 3" coupler, the nozzle is well centered on the compressor nut. When installed in a 2.5" or 4" intake, it's positioned slightly off center and resembles what's depicted in the examples above.

Note4: This technology works especially well with heavy methanol concentrations due to it's extremely fast evaporation speed.